Astragals and the evolution of glazing

Window design evolved!

In this blog post we explore the evolution of the glazing bar and why it is no longer used on modern buildings in favour of astragals or plant-on bars.

When sealed windows began to be manufactured, the size of the glass panes was the main limiting factor. Early glass panes were manufactured through flattening blown glass and the formulation used was not well developed, meaning that it was more fragile. These factors meant that the maximum size achievable was only about 0.3m2. A window this small would have restricted the light entering the room and made it basically unlivable – particularly at a time when electric lighting was not available. The solution was to create larger windows with multiple small panes separated by small pass through glazing bars (often referred to as Georgian bars due to the period of usage).

Glazing bars are solid pieces of timber mortise and tenoned into the window. The window is finished with individual glass panes that are fixed into place with linseed oil putty. The glazing bars are typically 20-30mm wide and feature a period mould to reduce the visible section.

As glass making technology improved, glass could be manufactured in larger and more stable panes. This led to windows being manufactured with only a single, vertical glazing bar (referred to as Victorian bars, again due to the time period of usage).

After the invention of double glazing, there was a dilemma on this front. Many people wanted to maintain the aesthetic of the Georgian and Victorian bars, but with the performance benefits of the new double glazing. Due to the weight and depth of the double glazing, it is not possible to support them in the rebates and timber sections previously used for glazing bars on single glazing. There are a number of possible solutions to this issue:

- Glazing bars with thicker timber sections and deeper rebates. These timber sections are generally 40-50mm across and even with the period mould, look unnaturally chunky.

- False bars inside the glazing. This is typically only done in cheaper uPVC windows, but a thin bar is fixed inside the double glazing and from a distance can give the effect that the window has Georgian bars. This is not suitable for any high quality job.

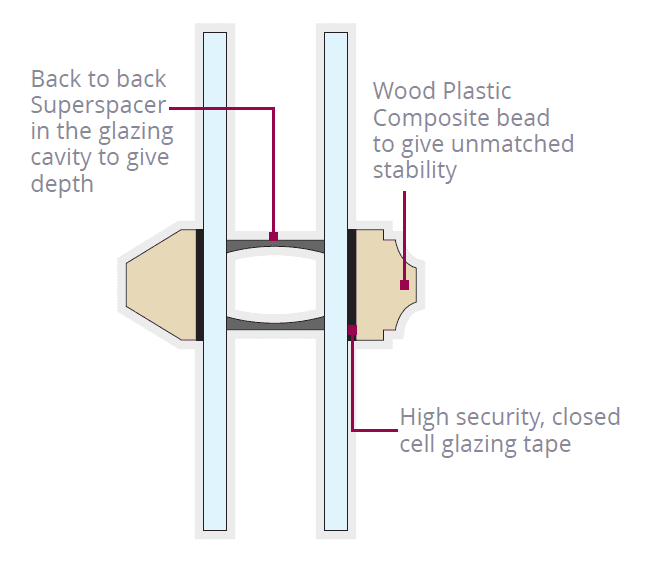

- Astragals (applied bars) with bonded bars. This option begins with the inclusion of a warm-edged bonded bar inside the glass unit, which is perfectly aligned with a traditional-style timber moulding adhered onto the face of both panes of glass (astragals). This gives the traditional appearance of full three-dimensional Georgian or Victorian bars, without reducing the energy efficiency of the window or the glass unit.

Modern astragals and glazing tapes are very stable and strong, allowing for long term adherence to the surface of the glass. At Gowercroft we use a specialist closer-pore, high security tape, and Q-Wood astragals (Wood Composite) to allow us to include these elements in our 10-year warranty. This method is considerably cheaper, much more energy efficient and more aesthetically pleasing than using full pass through glazing bars.

If you would like to discuss this further or see samples of each type of bar, then please do not hesitate to contact us.